The right quantity in the right profile:

Too much ballast in the track causes unnecessary costs. Too little or poorly distributed ballast reduces the quality of the track.

Plasser & Theurer offers a comprehensive selection of machines to shape the exact required quantity into the ideal profile. For operation on tracks and turnouts, in combination with cyclic-action or continuous-action tamping machines, for small rail networks and also for high-speed lines.

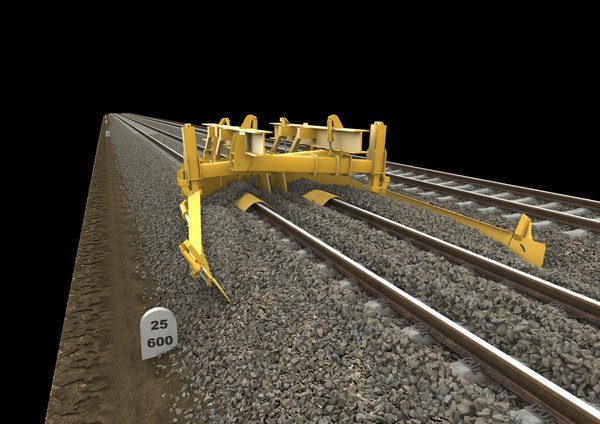

The ballast shoulder is profiled using shoulder ploughs which ensures that the correct angle of the embankment is produced. The shoulder ploughs draw the ballast into the upper area of the ballast bed towards the ballast crown. There the crown plough takes the ballast and distributes it in the track area according to the position of the baffle plates. Following this, a sweeper unit clears the ballast stones from the sleeper surfaces. This surplus ballast is unloaded either to the side of the track or, for greater cost-efficiency, carried on a conveyor belt to a storage hopper. Then the stored ballast is available for placement wherever there is a shortage of ballast.

The ballast bed secures the track geometry against track buckling. The technically correct design of the ballast bed cross-section is essential. This means that sufficient quantities of ballast are distributed uniformly and in the defined profile along the entire course of the line.

Sufficient ballast must be present for the tamping to achieve lasting results. Particularly in the past years, more commercial factors have been in favour of a uniform ballast cross-section because surplus ballast material ties up considerable financial capital. It is more cost-efficient to distribute the existing ballast correctly and uniformly and to reduce the quantity of new ballast required.